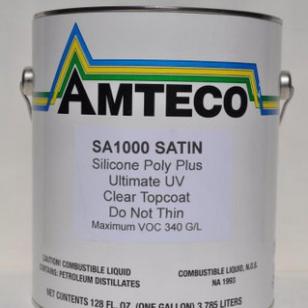

SA-1275™ "UV" (New SA-1000)

SA-1000/1275 SILICONE POLY PLUS ™

CLEAR SILICONE COPOLYMER VARNISH CLEARCOAT;

Includes Ultimate Performance "Tropical & Bamboo Formulas" (TBF)

(275 & 350 g/l VOC)

PRODUCT DESCRIPTION

The SA-1000 and SA-1275 Series Varnish Enamel Clearcoat is a uniquely designed clear topcoat version of our ultra-high performance SP-50 & SP-250 Silicone Poly Plus™ with unmatched "UV" resistance, adhesive strength and film strength. The Silicone Poly Plus system is famous for its superior performance to the current mil-spec/industrial systems used on military vessels & vehicles. Hereafter only SA-1000 will be mentioned but all applies to 275 g/l SA-1275 as well. SA-1000 is equipped with FSC's proprietary Ultimate "UV" technology for maximum screening when used as a true clear, protective topcoat or as a transparent coat. The SA-1000/1275 Topcoat can be applied directly to wood with transparent pigmentation recommended for exterior use direct-to-wood applications for enhanced longevity. The SA-1275 @ 275 gm/l VOC available to meet new South Coast/LA Area AQMD regulations. After a multi-year research program, we developed the "TBF Formulas" for maximum performance on bamboo and hardwoods…perfect for natural wood windows, doors, furniture, etc.

NOTE: Not available for purchase in Los Angeles, San Bernardino, Riverside and Orange Counties.

PRODUCT HIGHLIGHTS

*Top Performing Natural Wood Finish for Bamboo & Hardwoods as Pigmented or Clear Finish

*Lowest Life Cycle Costs of All Wood Varnish-like" Finishes for Bamboo & Hardwoods

*Absolutely Beautiful, "Deep" Finish…Excellent Film Clarity Gives full "Grain Reveal"

*Can Be Applied over Itself in Maintenance Applications

*#1 on Longevity in Marine (Including Boats), Desert and Coastal Environments

*Very Tough Film….Abrasion & Scratch Resistant

*Unmatched Adhesion and Flexibility, Even When Fully Catalyzed

*When Pigmented with FSC Automotive Pigments, Longevity Triples Over Use of True Clear

Breakthrough Technology Release for 2012: Tropical & Bamboo Formulations --Our latest research has guided us to the super-premium version of SA-1000/1275 referred as Tropical & Bamboo Formulas (TBF) for Bamboo and all hardwoods with enhanced organic growth resistance, UV packages and heavier film build for all exposures, particularly high humidity areas . TBF Formulas are the result of several years of lab and field testing with the unique sap/sugar bleed issues, adhesion and longevity issues for Bamboo and hardwood surfaces. TBF Formulas are simply the best there is for these surfaces where maximum longevity and beauty is desired. Light Cedar is the first color to be offered; a minimum batch size for other colors is 50-100 gal, color dependent.

The SA-1000 and TWP 300 Series super-premium wood finishes are made with the finest resins, water repellents, "UV packages" and pigments on the market today. The combination of SA-1000, the special 300 Standard and 300 QD (Quick Dry, California VOC compliant) Series represent the longest lasting way to stain and/or clear coat wood windows, wood doors, wood furniture, marine wood surfaces (above waterline applications only) and hardwoods currently available anywhere. FSC's systems have routinely been rated the #1 performing wood systems in North America over the past 15 years based on Texas A&M's famed Forest Products Lab testing and the top consumer magazine (June, 2000 last published #1 ranking). Call 800-579-8459 for additional information.

For enhanced longevity, we recommend that SA-1000 be applied over itself or our 300QD Series "Ultimate UV" and TBF Formulas pigmented clear wood finishes where trans-oxide screening is incorporated to further enhance the sun blockage properties of the system and maintain the color of the underlying wood substrate. For maximum longevity in direct-to-wood applications, the SA-1000 is also available as a transparent topcoat in limited colors with unmatched clarity and finish quality. With the increased protection from our unique transparent pigments, transparent SA-1000 finish is commonly used on Ipe, teak, mahogany, redwood, Douglas Fir, Alaskan Yellow Cedar (cypress), western red cedar and many other soft & hardwoods. Note: Routine Maintenance is easy with this system but must be done on a regular basis as described below to maintain the desired protection levels.

PRODUCT USES : SA-1000 is perfect for typical wood clear coat & varnish use applications. This includes wood windows, wood doors, hardwood & softwood applications of all types, wood ceilings, and marine interior & exterior applications. Interior fine finish uses include staircases, cabinets & railings. Following proper surface preparation, SA-1000 can be used as a clear or pigmented varnish topcoat to revitalize chalking surfaces that have been previously painted with oil-borne enamels or it can be used as a topcoat for the pigmented SA-3 Silicone Poly Plus system (following scuff sand and residue removal). SA-1000 can also be applied with proper surface preparation over spar varnishes, urethane-varnishes and other finishes to extend the coating system longevity but cannot prevent the underlying layers from disbonding. TBF Formulas recommended for all Bamboo surfaces and hardwoods including marine applications where maximum longevity is desired.

SURFACE PREPARATION:

All surfaces must have proper "tooth" to ensure adhesion -- whether applying over bare wood or existing solvent-borne coatings. Normally, "tooth" can be achieved by degreasing & cleaning, proper sanding and removal of residue & surface contamination. On bare wood, we recommend using 60 grit sandpaper on hardwoods and bamboo; 150-220 grit on softer woods -- preceded and followed by decontamination with FSC Wax & Grease Remover. When removing chalk or deglossing surface prior to SA-1000 application, apply FSC Wax & Grease Remover, abrade with maroon Scoth-Brite pad and wipe with FSC Wax & Grease Remover. Do not attempt to sand wood to "a polished look" as adhesion will be reduced. Apply Z-90 Wood Magic™ Plus (diluted 3 to 1 with hot/warm water by spray) followed by proper rinse or power wash is very effective to clean wood of organic growth, water spots and restore natural wood color prior to application. Talk to your FSC Coatings Consultant at 800-579-8459 for assistance. Note: Always test adhesion of system prior to undertaking full project applications. SA-1000 will not bond to oils, furniture polish, waxes or surface coatings containing penetrating oils, waxes or free silicones (like Thompson's WaterSeal™, our 400 & 500 Series wood finishes or Okon wood finish).

If the current surface coating is peeling or discolored, remove entire system to bare wood by stripping and/or sanding. All teak and Ipe oils as well as other wood oil treatments & polishes must be stripped too or system might fail/peel/discolor. We recommend Strip-This™ or Take-off Strippers for the job. Apply a generous amount and scuff surface with stiff nylon bristle brush and rough Scoth-Brite pads. Always test for effectiveness. After removal, wipe off stripper and dispose of appropriately. Use Z90 Wood Magic™ (2 to 1 dilution) to restore wood color and rinse off stripper residue (power wash best). Allow 2 days dry before applying 300 Series/300 QD "Ultimate UV" Stains and/or SA-1000 Silicone Poly Plus ™ Varnish Topcoat "Ultimate UV" coating system.

AVAILABLE FINISHES : It comes in full gloss (mirror finish, greater than 90 at 60° gloss meter) and satin sheens (25-35 gloss on 60° gloss meter). For semi-glosses, the full gloss and satin finishes can be "mixed to taste" in the field. SA-1000 can be pigmented with FSC's high performance pigments where transparent stains or colors are desired. SP-50 & SP-250 should also be considered whenever opaque finishes are required.

APPLICATION, THINNING & RECOAT TIMES

Conventional, HVLP or airless spray is recommended for the best finish clarity and texture. Can be applied by brush, roll or pad but can show streaks when applying SA-1000 satin finish. For best "look", use HVLP or conventional sprayer, thin at 10-25% with ZR Thinner ("0" VOC). Allow 72 hrs dry between coats when SA-1000 is uncatalyzed; overnight or at least 18 hrs when catalyzed at 16 oz/gal SA-1000.

Scuff sand lightly between coats to remove contamination followed by FSC Wax & Grease Remover wipe. Recoats times based on constant temperature of 75° F or higher, 50% R.H. or lower. 2 coats minimum required at 5.5-7 mils DFT; 3 coats recommended for complete grain fill at 8-10.5 mils DFT.

FSC recommends full coat spray applications -- not rag on, rag off applications . When wiping or rag applications are used, more frequent maintenance is required since actual coating system millage remaining on the surface is below spec thickness and resulting protection is dramatically reduced. When done, the coated surface must feel perfectly smooth with complete grain fill recommended for maximum longevity . Applying more thin coats -- rather than fewer heavy coats -- results in faster system cure.

When brushing or rolling, 2-3 times as many coats will be required to achieve proper mil film thickness - make sure you always have a wet brush or roller when using those techniques or millage will not be achieved.

For Bamboo and maximum longevity applications with standard and TBF Formulas, we recommend spray applying each coat in 2 passes separated by 30-45 minutes for solvent flash and increased cure rates. Catalyze with 16 oz. UH-1000 per SA-1000 gal for most TBF applications. Apply 1 full coat/day at 75° F & 50% or less Relative Humidity. Each coat to build 3-4 Mils DFT/coat using this procedure. Apply 3 coats for max longevity @ 9-12 Mils DFT.

PHYSICAL PROPERTIES:

WEIGHT PER GAL: 8.2-8.8 lbs./ gal VISCOSITY: 78-82 K.U.

FLASH POINT: T.C.C. 104°F VOC: 275 & 345 gm/l.

WEIGHTS SOLIDS: 63-72% VOLUME SOLIDS: 56-70%

60 DEG. GLOSS: Gloss= 85+; Satin= 30-40 DRY TIME @77°F: S.T.- 2-3hrs.

DRY HARD: 24 HRS. @ 2.0 mil DFT. DRY TO RECOAT: 48-72 HRS. (77° F)

VOC: SA-1000 350g/l; SA-1275 275 g/l

UH-1000 ALIPHATIC URETHANE SUPER CATALYST & FSC ACCELERATOR

To speed up cure, the UH-1000 Catalyst can be added up to 32 oz/gal SA-1000. UH-1000 can also be added to increase hardness and gloss without sacrificing flexibility. Prior to adding UH-1000, add 8 oz of ZR Thinner & mix to increase solvency of system. For most door, window, furniture and cabinet applications, add UH-1000 @ 8 oz/gal. Forinterior or exterior flat surfaces such as rails, tables or countertops, add catalyst @ 16-32 oz/gal to increase scratch resistance. For interior floors, we recommend 32 oz UH-1000/gal (consider Poly-Grit ™ for non-slip properties where needed).

For fastest possible cure rates, FSC Accelerator is also available to acceleratecure rates at lower temperatures (less than 70° F) or where production conditions require its use. Add FSC Accelerator after adding ZR Thinner & UH-1000 Catalyst and proper mixing of blended components with power mixer; mix again with power mixer after adding FSC Accelerator (be careful to not entrain air with excessive mixing or mixing velocity). Do not try to apply coats too quickly, even when coating appears to be firm, because solvent can be trapped resulting in shrinkage & surface film changes after 7-30 days.

Notes: 1) Catalyst use will increase sheen of the satin formulation; the more catalyst added, the more sheen that will develop. 2) When applying SA-1000 with the UH-1000, use fresh air supply system and follow all OSHA instructions associated with applying urethane systems -- especially important when spraying a catalyzed system.

POT LIFE-Uncatalyzed, Catalyzed & Accelerated: Uncatalyzed, the SA-1000 has no pot life restraints but will develop a surface skin if left open to the air (can be ruined if exposed to air too long).Once catalyzed with UH-1000, SA-1000 has a pot life of 4-6 hrs (with material thinned & container closed). With FSC's Accelerator, the catalyzed SA-1000 pot life is cut 65-80%; at 77°F, pot life is 45 min.

SPREAD RATE & NUMBER OF COATS

Apply at least 2 coats of SA-1000 at 5.0 mils wet per coat (5.5-7.0 Dry Mils total). 3 coats are better since system longevity is directly related to mil film thickness (8-10.5 Dry Mils total). Uncatalyzed, allow 72 hrs dry between coats for proper film through-dry (we recommend catalyzing every SA-1000/1275 job @ 16 oz/gal or higher). When catalyzed with UH-1000 @ 16 oz/gal, allow overnight dry (at least 18 hr dry between coats). Do not exceed 6 mils WET/coat as dry time will become excessive & film toughness will be decreased. Finish can be force cured.

Apply each coat as 2-3 thin passes with 30-45 min. between passes . Thin passes are always better to prevent solvent trap, bubbles & craters. Remember that it is common to lose 25-40% of the SA-1000 as overspray when spraying with airless or conventional application; that loss is cut in half with HVLP application. Use wet film gauge to check thickness of each coat.

If thinned for spray at 15-25% with ZR Thinner, three coats are required in most cases to achieve desired film thickness.

@300 SQ FT/GAL Theoretical (no thinning) 5.0 mils wet film =3.5 mils dry film

@350 SQ FT/GAL Theoretical 4.5 mils wet film =3.0 mils dry film

@400 SQ FT/GAL Theoretical 4.0 mils wet film =2.6 mils dry film

@500 SQ FT/GAL Theoretical 3.2 mils wet film =2.1 mils dry film

ROUTINE MAINTENANCE -- Very Important!

Apply Clear SA-1000 Yearly in Full Weather Vertical Applications; 3-6 months in Horizontal applications. It is absolutely crucial that inspections and routine maintenance be taken on a yearly basis when fully exposed to weather to prevent aging of the underlying substrate and resulting adhesion loss or peeling. It is easy -- use maroon Scoth-BriteÒ pad to obtain "tooth" in surface & degloss, remove residue with appropriate cleaner and apply 1-2 coats of SA-1000 "Ultimate UV" formula at 400 sq ft/gal or 2.6 mils dry film per coat. If wiping or rag on/rag off applications are used , routine maintenance will be increased in frequency to every 3-6 mo. since insufficient millage will result .

Transparent pigmented SA-1000/1275 will have much longer maintenance cycles than true clear applications. However, we recommend yearly recoats on all horizontal applications - especially important with hardwoods. Ipe, Mahogany, Teak and other exotic hardwoods have free oils that migrate and unique grain patterns which can cause even more frequent disbonding which must be monitored every few months.

Important Notes :

1) Uncatalyzed SA-1000 requires 1-2 months cure to achieve maximum hardness, scratch resistance and toughness at 70 degrees F and 50% Relative Humidity. Please use catalyst.

2) Always scuff sand surfaces -- coated or uncoated -- to ensure "tooth" and proper adhesion.

3) Allow proper cure time between coats or lifting and wrinkling will result. Spray more thin coats rather fewer heavy coats for optimal dry and cure rates.

4) Use ZR Thinners only to thin. Do not thin with straight acetone, xylene or toluene as lifting & wrinkling may be aggravated and VOC compliance may be compromised.

5) Routine Maintenance must be done or film failure can result.